"Rock Bottom" (rockbottom81)

"Rock Bottom" (rockbottom81)

09/20/2017 at 10:45 ē Filed to: None

6

6

8

8

"Rock Bottom" (rockbottom81)

"Rock Bottom" (rockbottom81)

09/20/2017 at 10:45 ē Filed to: None |  6 6

|  8 8 |

Theyíre stupid expensive, but they are damn cool. Years ago, I worked on a project that could have used them, but we ended up strain-gauging a different component in the assembly. It was the right decision, but it still made me sad. If Iím ever super rich, Iím going to randomly scatter these throughout my car and just collect data for no good reason. I will also host C4 Corvette demolition derbies. Youíre all invited.

http://www.strainsert.com/product-categories/force-sensing-bolts-studs/

miadaman? yes please

> Rock Bottom

miadaman? yes please

> Rock Bottom

09/20/2017 at 11:15 |

|

Itís so beautiful *shed a single enginerd tear*

How much weaker is it comparing to a regular ass bolt?

Rock Bottom

> miadaman? yes please

Rock Bottom

> miadaman? yes please

09/20/2017 at 12:15 |

|

Iíd bet that itís similar to a comparable standard fastener. I think the weak point of a fastener is generally the threads? Any mechanical engineers here have an opinion?

miadaman? yes please

> Rock Bottom

miadaman? yes please

> Rock Bottom

09/20/2017 at 12:37 |

|

Coincidentally I am a mechanical engineer - though I donít work with bolts and screws anymore. I shouldíve been clearer - I was wondering about the shear and bending load.

gogmorgo - rowing gears in a Grand Cherokee

> miadaman? yes please

gogmorgo - rowing gears in a Grand Cherokee

> miadaman? yes please

09/20/2017 at 13:03 |

|

Itís only going to reduce the strength of the bolt by a similar amount to a rod the size of the hole drilled. I imagine these holes will be pretty small if theyíre putting them into 1/4" bolts. They shouldnít need to be all that big either. I imagine if its enough of a reduction that itíll cause issues, you wouldíve wanted a bigger bolt there anyhow.

Rock Bottom

> miadaman? yes please

Rock Bottom

> miadaman? yes please

09/20/2017 at 13:04 |

|

I did find this little nugget on the site:

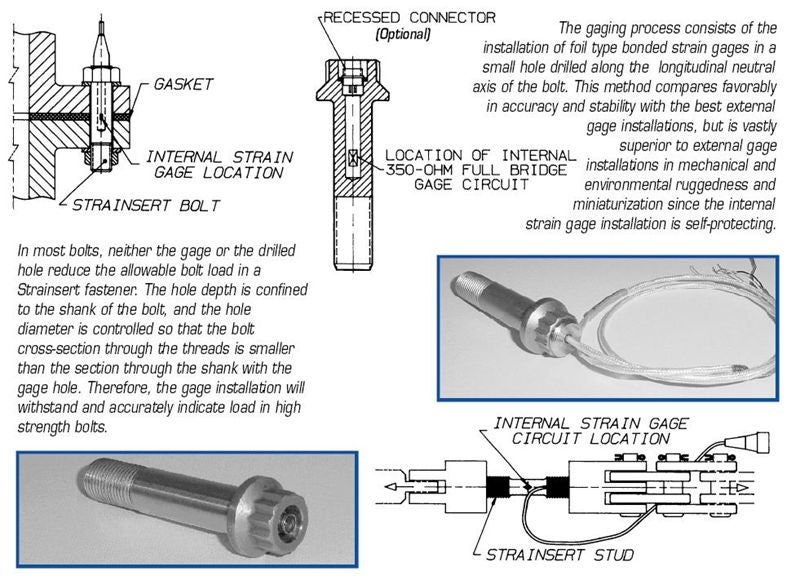

In most bolts, neither the gage or the drilled hole reduce the allowable bolt load in a Strainsert fastener. The hole depth is confined to the shank of the bolt, and the hole diameter is controlled so that the bolt cross-section through the threads is smaller than the section through the shank with the gage hole. Therefore, the gage installation will withstand and accurately indicate high strength loads.

So I guess I would interpret that to mean theyíre able to retain normal strength, which is neat. Iím an aerodynamicist, so fasteners are way outside of my wheelhouse, but I believe shear strength of a fastener is generally meaningless as long as the bolt clamping load is not exceeded? I think the shear load through a properly torqued joint it born by the friction of the two surfaces being clamped by the bolt? Now Iím going to have to dig up my old text books when I get home tonight!

miadaman? yes please

> Rock Bottom

miadaman? yes please

> Rock Bottom

09/20/2017 at 13:22 |

|

Sounds like theyíre saying this is a bolt you use for tensile load by the way theyíre comparing cross section areas of different segments of the bolt. I donít see how hollowed tube would have more shear strength than solid piece of metal. Neat contraption, Iíll take 50 Jerry.

miadaman? yes please

> gogmorgo - rowing gears in a Grand Cherokee

miadaman? yes please

> gogmorgo - rowing gears in a Grand Cherokee

09/20/2017 at 13:24 |

|

Small holes introduces stress concentrations, but looks like itís probably made for tensile loads where it is less significant!

gogmorgo - rowing gears in a Grand Cherokee

> miadaman? yes please

gogmorgo - rowing gears in a Grand Cherokee

> miadaman? yes please

09/20/2017 at 13:33 |

|

This is true.

Iíd point out that generally bolts shouldnít be loaded in shear anyhow, with the shear load being born by the friction between the two clamped segments. The only exception to this os where the bolt is also a pivot point, such as at the end of a suspension link, although in that case the strain wouldnít be measurable very easily by this method. You can bend a bolt pretty far before thereís much change in overall length. Also the clamping force in that scenario isnít very high, just enough a nut wonít spin itself back off.